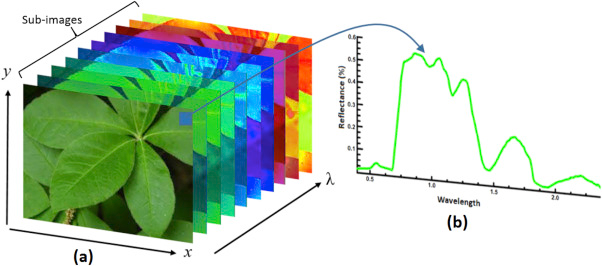

For the food sector, quality control is as fundamental as in the manufacturing sector. In fact, in the food sector not only must geometrical characteristics such as shape, size, visual defects be respected, but also quality features intrinsic, linked to biological parameters of the matrix itself. The automatic quality control of every single product is desirable in the production process, since the end customer requires that every single object complies with both in terms of visual expectations that sensory and safety. The challenge of innovation consists in the development of new paradigms of interaction among control systems and automatic sorting machines that can be integrated in the food production lines. This so to reach a new frontier of automatic analysis capacity through spectral and hyperspectral detection of qualitative and quantitative parameters of semi-finished products. Data are processed by means of deep learning and machine learning paradigms. These algorithms can set a new level of reference in the industrial sector of automatic sorting machines. In addition to that, advanced robotic actuators guarantee both flexibility and productivity to the process.